Modern Construction Excellence {Exclusive patent}

THE PRE-CAST REINFORCED CONCRETE (CCI MODULE) SYSTEM

The Module Construction System is the latest technology in the building field not only because it saves considerable time in site execution programs, but also for its flexibility which allows to make all the designs or geometrical figures of any dimensions. In addition, it saves lots of materials and is considerably cost effective.1

General Specifications:

This system relies basically on the utilization of the common reinforced concrete currently used in the different projects, with the same specifications – according to the structural calculations determining the mixture type (K1 & K2 & K3) etc. and the type of cement (lean or resistant…).

These concretes are made at the plant and cast in special sector-shaped moulds (CCI). These moulds are made of iron, thus timber is saved.

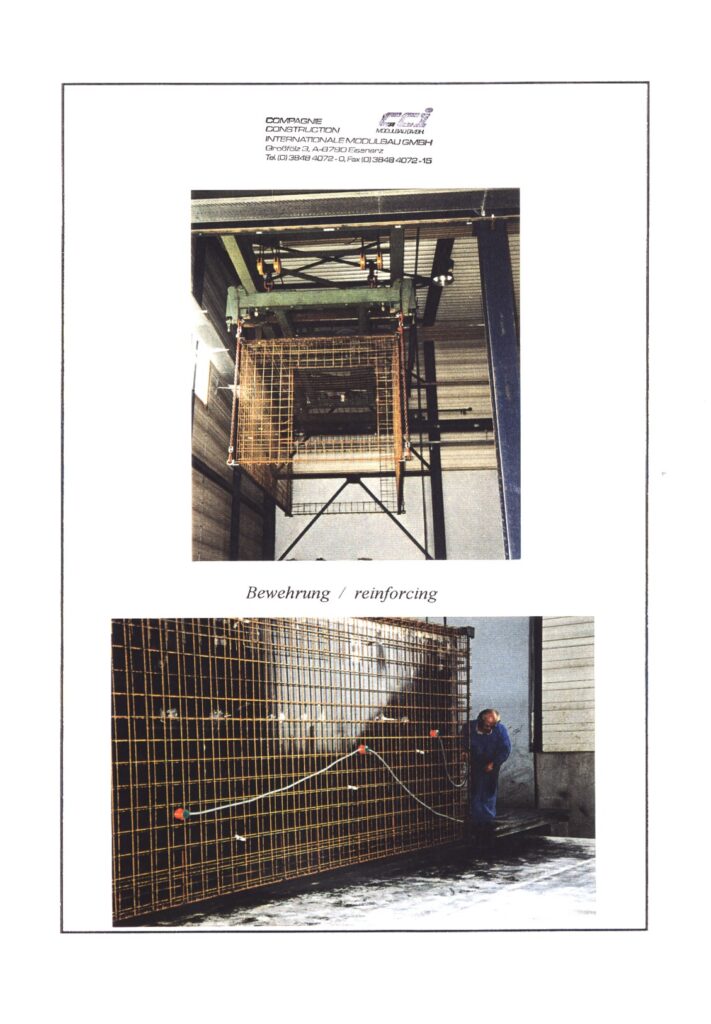

The construction structure is prepared of the reinforcement iron and executed according to the structural calculations. This structure is placed inside these moulds again according to the architectural drawings as to window and door openings, figures, dimensions and heights. The inner side of the mould is formed according to the architectural drawing of the external or internal front.

The built-in electrical and sanitary installations are made according to the electrical and sanitary drawings. The air-conditioning openings, if any, are also made in the same mould.

Iron pieces (plates) are fitted on the mould corners to be soldered for assembling purposes.

The mould is closed and the reinforced concrete is cast inside according to the concrete material and the project specifications.

These moulds are cast in three shapes: to form the flooring, the ceiling and the side walls incorporating the moulded windows and doors, forming an integral room or hall. However, it is possible to assemble more than one mould to construct bigger areas, and at the same time the mould itself can be expanded according to the architectural drawings.

The concrete material is processed for eight hours, thus each mould can be used for making three modules daily.

The modules are then transported to the building site to be put in place, where each module is soldered to the other in the allocated places. Thus all the black structure is assembled containing all the electrical and sanitary installations as well as air-conditioning openings, to be followed by internal and external finishings.1

A) Advantages of the CCI Module Product:

The project cost is reduced.

The project is accomplished with the optimum specifications.

Fault-free installation of prefab buildings with the best performance.

The project is completed in a record time.

Considerable possibility and flexibility for various designs of internal and external fronts.

Worldwide applicability covering all the various basic items of the project.

Continued and internationally approved production with international specifications.

Resists earthquakes up to 8.2 according to the Richter scale.2

B) Benefits to the Companies as to Future Planning and Development:

Internal Benefits: (Utilization of the product for the company’s interest)

Creating new business horizons in the country.

This business could, if the companies so desire, form the core for new management of planning and development.

Availability of materials such as concretes or brickworks would reduce the cost price, thus paving the way for an increase of the houses.

Engaging the companies’ staff of every specialization in the business.

As the product saves at least 70% of the execution time of any construction project, the opportunity is given to supply the product to the governmental departments and ministries projects as well as to private projects.

External Benefits:

Creating business opportunities in the neighbouring countries.

Possibility of having agencies or plants in various markets outside the country.2

Computation of Quantities:

One square meter represents about 13% of a cubic meter of reinforced concrete, with 12 cm thickness for the walls and the ceiling – in ordinary conditions.

In other words, one meter of ground needs 13% of reinforced concrete cubic meter to cover the side walls and the ceiling, including all the electrical, sanitary, air-conditioning works, etc.

To calculate the prices of these quantities, we have to refer to the concrete cost prices adopted at the company. Moreover, this also relates to the module thickness as determined by the designer of every individual project.

An economic feasibility study is required to determine the capital turnover schedule.

Moreover, a study should be performed on the prices of materials charged with the relevant electrical, sanitary, air-conditioning works, etc., in addition to the skilled and unskilled labour and the sale and distribution rates